#219372 - 22/06/2004 13:31

Buttons - Redesign for low volume production

Buttons - Redesign for low volume production

|

carpal tunnel

Registered: 17/12/2000

Posts: 2665

Loc: Manteca, California

|

Currently the buttons are designed for minimum after molding hand work. Which is good for a unit produced in the thousands, preferrably millions.

For production in the hundreds where the end user can supply some hand work, (think plastic model kit) It may be preferrable to make the buttons in two parts. A cap and a cup. The end user would trim and cement them together. (something unthinkable in a high volume productions) From the backside they would not look exactly the same. Why should they? We only look at the front side.

sorry about the blinding white background. Is there a way to replace an attachement?

PS. I forgot to mention why. This kind of button can be made with cored straight pull molds. See Protomold's website.

Edited by gbeer (22/06/2004 13:43)

_________________________

Glenn

|

|

Top

|

|

|

|

#219373 - 22/06/2004 14:02

Re: Buttons - Redesign for low volume production

[Re: gbeer]

Re: Buttons - Redesign for low volume production

[Re: gbeer]

|

Carpal Tunnel

Registered: 08/02/2002

Posts: 3411

|

I've been studying the original buttons desperately trying to find a feature that would prevent straight pull molding.

What am I missing?

_________________________

Mk2a 60GB Blue. Serial 030102962

sig.mp3: File Format not Valid.

|

|

Top

|

|

|

|

#219374 - 22/06/2004 21:43

Re: Buttons - Redesign for low volume production

[Re: genixia]

Re: Buttons - Redesign for low volume production

[Re: genixia]

|

carpal tunnel

Registered: 17/12/2000

Posts: 2665

Loc: Manteca, California

|

Ok, I went and took my player apart to look at the button back side to refresh my memory. They can be made straight pull as is. But half of that mold is relatively difficult to cut.

The cap side mold is an open pocket. Relativly easy to cut. The socket side is tougher. Thin walls with notches and a protruding core. All have to be machined using small mill cutters. That, or additional pins (cores) have to be inserted into the mold. More parts.

I think the molds would be easier to make if the button was two parts. Cap and socket. All mold surfaces would be either a simple pocket or a protruding core. Larger diameter tools can be used. Polishing is easier. Easier is cheaper.

This job is really bounded by keeping the front end costs as low as possible. If that can be done by letting the end user do some self assembly...

_________________________

Glenn

|

|

Top

|

|

|

|

#219375 - 22/06/2004 21:55

Re: Buttons - Redesign for low volume production

[Re: gbeer]

Re: Buttons - Redesign for low volume production

[Re: gbeer]

|

old hand

Registered: 15/07/2002

Posts: 828

Loc: Texas, USA

|

The link is not working for me so I'm not sure what a cored straight pull mold is. If it's what I think it is, it looks similar to this

but, in the instance of protomold, in aluminum for rapid prototyping. If so, I'm not sure why a 2 part button would be necessary. There are no undercuts that would prohibit a straight pull on the buttons or knobs with a 2 part mold. (Actually there is one on the down button but it can be modified.) If the cutting edges of the molde are placed at the base of the button before the stalk then they should come out of the mold just fine.

Am I misunderstanding what a cored straight pull mold is?

Edited by Mach (22/06/2004 21:57)

|

|

Top

|

|

|

|

#219376 - 22/06/2004 22:00

Re: Buttons - Redesign for low volume production

[Re: gbeer]

Re: Buttons - Redesign for low volume production

[Re: gbeer]

|

old hand

Registered: 15/07/2002

Posts: 828

Loc: Texas, USA

|

Okay I wasn't considering how the mold gets made. I understand why you want a two part button but doesn't this make the knob problematic. For the button base, I'd consider using the short Farnell button caps as either the base pieces or the prototype for the base pieces. They are much more consistent than the Empeg ones.

|

|

Top

|

|

|

|

#219377 - 23/06/2004 00:12

Re: Buttons - Redesign for low volume production

[Re: gbeer]

Re: Buttons - Redesign for low volume production

[Re: gbeer]

|

Carpal Tunnel

Registered: 08/02/2002

Posts: 3411

|

Hmm. Somewhere else, someone has mentioned that for best diffusion we need the buttons more filled than the originals anyway. That core needed be so big.

_________________________

Mk2a 60GB Blue. Serial 030102962

sig.mp3: File Format not Valid.

|

|

Top

|

|

|

|

#219378 - 23/06/2004 10:34

Re: Buttons - Redesign for low volume production

[Re: genixia]

Re: Buttons - Redesign for low volume production

[Re: genixia]

|

carpal tunnel

Registered: 17/12/2000

Posts: 2665

Loc: Manteca, California

|

There are a couple of reasons to core out a part. With high volume production, even a few percent material savings can be worth big bucks. Another is that plastics shrink when they cool, thick sections shrink more than thin.

Getting the light to refract thru the part, more evenly illuminating the cap, is a really complex optical problem. I think that's why most backlit buttons are translucent instead of transparent. Even then odd geometries can lead to uneven results.

Unless the casting shop thinks filling in the button would cause the outward appearance to suffer, the cost of filling them in will likely be lost compared to the scrap. I seem to remember a picture in one of the galleries showing a bin full of faceplates that hadn't fully filled the molds.

A tip for any one with hollow transparent buttons now. If you want to fill them in, you will need to fill them in with a material that has a matching Index of Rrefraction. Otherwise the light will still bounce around inside the button just the same as it already does.

_________________________

Glenn

|

|

Top

|

|

|

|

#219379 - 23/06/2004 10:50

Re: Buttons - Redesign for low volume production

[Re: gbeer]

Re: Buttons - Redesign for low volume production

[Re: gbeer]

|

Carpal Tunnel

Registered: 08/02/2002

Posts: 3411

|

I wonder if the empeg guys still have the CAD files for the originals? It'd be worth submitting them for an estimate as-is.

_________________________

Mk2a 60GB Blue. Serial 030102962

sig.mp3: File Format not Valid.

|

|

Top

|

|

|

|

#219380 - 23/06/2004 19:52

Re: Buttons - Redesign for low volume production

[Re: genixia]

Re: Buttons - Redesign for low volume production

[Re: genixia]

|

pooh-bah

Registered: 19/09/2002

Posts: 2494

Loc: East Coast, USA

|

Great idea. I'll e-mail Rob V about the CAD's, asking him to forward the message to the appropriate person if he's not the one. I'll also ask about copyright on the button design itself, because I don't want to infringe or anything.

_________________________

- FireFox31 110gig MKIIa (30+80), Eutronix lights, 32 meg stacked RAM, Filener orange gel lens, Greenlights Lit Buttons green set

|

|

Top

|

|

|

|

#219381 - 23/06/2004 20:50

Re: Buttons - Redesign for low volume production

[Re: FireFox31]

Re: Buttons - Redesign for low volume production

[Re: FireFox31]

|

old hand

Registered: 15/07/2002

Posts: 828

Loc: Texas, USA

|

|

|

Top

|

|

|

|

#219382 - 24/06/2004 11:02

Re: Buttons - Redesign for low volume production

[Re: Mach]

Re: Buttons - Redesign for low volume production

[Re: Mach]

|

carpal tunnel

Registered: 23/08/2000

Posts: 3826

Loc: SLC, UT, USA

|

I emailed Rob to see if he still has the CAD files. Will advise....

|

|

Top

|

|

|

|

#219383 - 24/06/2004 18:55

Re: Buttons - Redesign for low volume production

[Re: FireFox31]

Re: Buttons - Redesign for low volume production

[Re: FireFox31]

|

pooh-bah

Registered: 19/09/2002

Posts: 2494

Loc: East Coast, USA

|

I have received the CAD files for the buttons from Rob V (and I hope that I'm not breaking any rules by saying that here). Hopefully Loren's more-capable hands have it now too. Now that a few of us have received it from him, we should probably not push our luck by requesting any more. Thanks to Rob for letting us use this for the project.

Some notes from Rob:

The button CADs are subject to copyright. He granted us the right to use it for this project only. The CADs are not to be distributed publicly. If we want to use the buttons for any other project, please contact Rob first.

The CAD files are in SolidWorks format.

Loren, do you have access to SolidWorks at your job? It would be great to modify the CADs to fill in the blank space for better illumination (as Stu experienced). I asked Rob if we were allowed to modify the CADs because of the copyright. I will post back here once I hear about it.

And I must say Mach, you are the BBS searching machine! (a compliment, you know, saying that you work as hard as a machine does)

_________________________

- FireFox31 110gig MKIIa (30+80), Eutronix lights, 32 meg stacked RAM, Filener orange gel lens, Greenlights Lit Buttons green set

|

|

Top

|

|

|

|

#219384 - 25/06/2004 21:52

Re: Buttons - Redesign for low volume production

[Re: FireFox31]

Re: Buttons - Redesign for low volume production

[Re: FireFox31]

|

pooh-bah

Registered: 19/09/2002

Posts: 2494

Loc: East Coast, USA

|

Yes, Rob said we can modify the CAD as necessary. Now, we just have to do it.

_________________________

- FireFox31 110gig MKIIa (30+80), Eutronix lights, 32 meg stacked RAM, Filener orange gel lens, Greenlights Lit Buttons green set

|

|

Top

|

|

|

|

#219385 - 01/07/2004 21:05

Re: Buttons - Redesign for low volume production

[Re: FireFox31]

Re: Buttons - Redesign for low volume production

[Re: FireFox31]

|

carpal tunnel

Registered: 23/08/2000

Posts: 3826

Loc: SLC, UT, USA

|

Nope. All i have is Maya... no solidworks. Rob Vreeland might have access to it however...

|

|

Top

|

|

|

|

#219386 - 17/07/2004 20:44

Re: Buttons - Redesign for low volume production

[Re: gbeer]

Re: Buttons - Redesign for low volume production

[Re: gbeer]

|

old hand

Registered: 15/07/2002

Posts: 828

Loc: Texas, USA

|

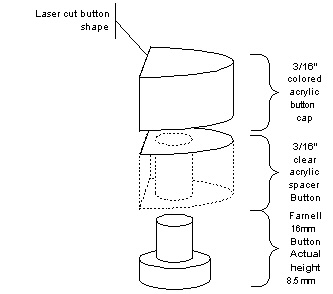

Taking the concept of a redesign in another direction. AFAIK, the intent of the coloring the button is to match the lens color so why not just use the lens plastic instead of casting resin. Based on some rough measurement, 2 pieces of 3/16" plastic and a farnell button cap could be used to make the buttons. Assuming that the button shapes could be laser cut, buttons could be etched with symbols or text while cutting. Also metal caps could be done similar to Beaker's design.

The downside is that they will require assembly and sanding but I think it is possible to do. The Empeg buttons are not the same height either so there would be a difference. I'm not sure how noticeable it would be though. Anyone see any reason this wouldn't work? I am curious as to why the farnell button cap base design was not used for the Empeg buttons. Was the intent to allow more free play in the Empeg buttons than the Farnell?

I've gotten little response from the casters that I have contacted so I'm going to chase this direction for awhile. I'll keep every one posted as things change.

|

|

Top

|

|

|

|

#219387 - 18/07/2004 12:40

Re: Buttons - Redesign for low volume production

[Re: FireFox31]

Re: Buttons - Redesign for low volume production

[Re: FireFox31]

|

pooh-bah

Registered: 25/08/2000

Posts: 2413

Loc: NH USA

|

|

|

Top

|

|

|

|

#219388 - 18/07/2004 19:03

Re: Buttons - Redesign for low volume production

[Re: Mach]

Re: Buttons - Redesign for low volume production

[Re: Mach]

|

pooh-bah

Registered: 19/09/2002

Posts: 2494

Loc: East Coast, USA

|

Using the Farnell base is so tempting; that's a really good idea. I wonder, could laser cutting give the features on the face of the buttons? Probably not the texture, but the Left and Right curves and the Up dome shape?

I wonder if a similar approach could be used for a knob. Finding matching shafts and sticking on laser cut pieces. But same there, can it give the dipped in middle and little bumps on the outside?

My biggest fear of multi-piece buttons has been the glue. What kind could be used, would it be provided with the buttons upon sale, and, most importantly, would a layer (or two) of glue obscure the transmission of light? And also, I've never had good results glueing flat surfaces to eathother. Would that post a problem with this redesign?

_________________________

- FireFox31 110gig MKIIa (30+80), Eutronix lights, 32 meg stacked RAM, Filener orange gel lens, Greenlights Lit Buttons green set

|

|

Top

|

|

|

|

#219389 - 18/07/2004 20:18

Re: Buttons - Redesign for low volume production

[Re: FireFox31]

Re: Buttons - Redesign for low volume production

[Re: FireFox31]

|

old hand

Registered: 15/07/2002

Posts: 828

Loc: Texas, USA

|

Texture would be smooth. The shapes would be flat to rounded and would likely not be the same surface shape as the Empeg buttons.

The knob, at least for the D key Mk2a, could be done the same way. 1 piece of plastic to handle the key, the other piece could be a plastic cap or a metal cap. That way the knob could be end glow or side glow. While the Emepg knob could be matched, it would likely not be exact if done at all.

As to the glue, with a jig that would hold the pieces in alignment and acrylic or even super glue, I think it could work. I am concerned about bubbles but that may not be such an issue when they're clamped together.

I'll try some prototypes to test some of these guesses. I'll post back when I know more.

|

|

Top

|

|

|

|

|

|